Sandwich Panel Materials and Insulation: Uses and Benefits

Sandwich panels have revolutionized modern construction by combining structural strength with exceptional thermal insulation properties. These innovative building materials consist of two outer layers bonded to an insulating core, creating a lightweight yet durable solution for various construction applications. From residential homes to commercial buildings, sandwich panels offer superior energy efficiency, faster installation times, and cost-effective building solutions that meet contemporary construction demands.

Modern construction increasingly relies on advanced materials that deliver both performance and efficiency. Sandwich panels represent a significant advancement in building technology, offering architects and builders a versatile solution that addresses multiple construction challenges simultaneously. These engineered materials have become essential components in contemporary building projects across Italy and throughout Europe.

What Are Sandwich Panels?

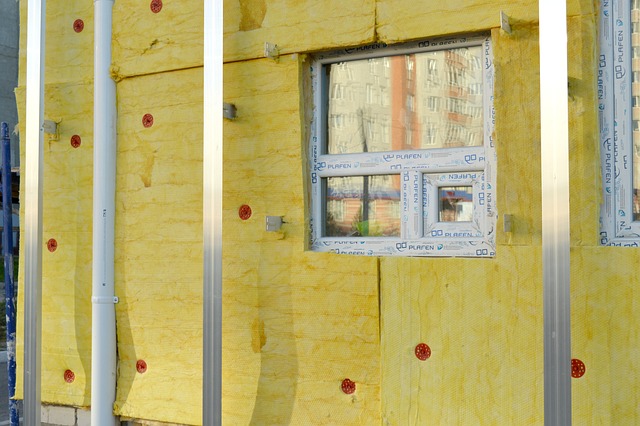

Sandwich panels are composite building materials consisting of three distinct layers: two outer facings and an insulating core material. The outer layers, typically made from materials like steel, aluminum, or fiber cement, provide structural strength and weather protection. The core material, positioned between these facings, delivers thermal insulation and additional structural support. This three-layer construction creates a unified building element that combines multiple functions into a single component.

The manufacturing process involves bonding these layers under controlled conditions, creating a strong adhesive connection that ensures the panel performs as a unified structural element. Various thicknesses are available, typically ranging from 50mm to 250mm, allowing builders to select panels that meet specific insulation requirements and structural loads.

Insulation Materials Used in Sandwich Panels

The core insulation material significantly influences the panel’s thermal performance and application suitability. Polyurethane (PUR) foam offers excellent thermal insulation properties with low thermal conductivity values, making it ideal for applications requiring superior energy efficiency. This material also provides good structural strength and moisture resistance.

Polyisocyanurate (PIR) foam delivers enhanced fire resistance compared to standard polyurethane while maintaining excellent insulation properties. Mineral wool cores, made from rock wool or glass wool, provide superior fire resistance and acoustic insulation, making them suitable for buildings with strict fire safety requirements.

Expanded polystyrene (EPS) cores offer cost-effective insulation with good thermal performance, though with slightly lower insulation values than polyurethane options. Each core material brings specific advantages, allowing builders to select panels that match project requirements and budget considerations.

Key Benefits of Sandwich Panels

Sandwich panels deliver numerous advantages that make them attractive for modern construction projects. Their excellent thermal insulation properties significantly reduce energy consumption for heating and cooling, contributing to lower operational costs and improved environmental sustainability. The lightweight nature of these panels reduces structural loads on buildings, potentially allowing for more economical foundation and structural designs.

Installation speed represents another significant advantage. Sandwich panels can be installed quickly compared to traditional construction methods, reducing labor costs and project timelines. Their factory-manufactured precision ensures consistent quality and dimensional accuracy, minimizing on-site adjustments and installation complications.

The panels also provide excellent weather resistance, creating effective barriers against moisture, wind, and temperature variations. Many sandwich panel systems include integrated sealing solutions that eliminate thermal bridging and air infiltration issues common in traditional construction.

Residential Applications

In residential construction, sandwich panels find applications in various building elements. Wall systems using sandwich panels create highly insulated building envelopes that meet stringent energy efficiency standards. These systems are particularly popular in passive house construction and other high-performance residential projects.

Roof applications utilize sandwich panels to create insulated roof systems that combine structural support with thermal protection. The panels can span significant distances without intermediate support, allowing for flexible interior layouts and reduced structural complexity.

Sandwich panels also serve effectively in residential extensions and renovations, where their lightweight properties and excellent insulation performance make them ideal for improving existing building performance without requiring extensive structural modifications.

Choosing the Right Sandwich Panel for Your Project

Selecting appropriate sandwich panels requires careful consideration of multiple factors. Thermal performance requirements, determined by local building codes and energy efficiency goals, influence core material selection and panel thickness. Structural loads, including wind and snow loads, affect facing material selection and panel specifications.

Fire resistance requirements may mandate specific core materials, particularly in residential applications where building codes specify fire performance standards. Acoustic performance considerations become important in residential settings where sound transmission control is required.

Budget considerations also influence panel selection, as different core materials and facing options carry varying costs. Professional consultation with suppliers and structural engineers ensures optimal panel selection that balances performance requirements with project economics.

| Panel Type | Core Material | Thermal Performance (W/m²K) | Cost Range (€/m²) |

|---|---|---|---|

| Standard PUR | Polyurethane | 0.20-0.25 | 25-35 |

| PIR Enhanced | Polyisocyanurate | 0.18-0.23 | 30-45 |

| Mineral Wool | Rock Wool | 0.25-0.30 | 35-50 |

| EPS Budget | Expanded Polystyrene | 0.28-0.35 | 20-30 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Sandwich panels continue to evolve with advancing technology and changing construction requirements. Their combination of thermal performance, structural capability, and installation efficiency makes them increasingly valuable in contemporary construction. As energy efficiency standards become more stringent and construction timelines more demanding, sandwich panels offer practical solutions that address multiple construction challenges simultaneously. Understanding their properties and applications enables builders and homeowners to make informed decisions about incorporating these advanced materials into their construction projects.